Brake Bands

All of our brake bands are manufactured here in our facility in the USA. At Unlimited Machine, we do not outsource any parts of our brake bands as everything is done in house. We manufacture them using certified steel which is heat treated and allows our bands to flex more, which eliminates premature cracking. All bands go through a quality control inspection before leaving our facility. This ensures correct shaping and standoff to eliminate linkage issues. We stock a variety of brake bands which include, but are not limited to: National, Oilwell, Ideco, Continental Emsco, Cooper, Franks, Mid-Continent (Unit), Skytop, Brewster, and Skytop. Customized brake band can be build upon request.

In order to trace our bands back to the manufactured date, we stamp serial numbers.

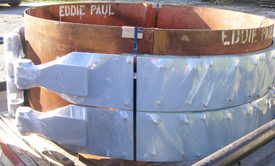

RECONDITIONED BRAKE BANDS

At Unlimited Machine, we specialize in reconditioning used brake bands. Bands are inspected for cracks and to ensure the pin holes are within tolerance. Upon completion of Magnetic Particle Inspection (MPI), a process used to determine if the bands are cracked, we determine if the brake bands can be reconditioned to “like new.” If it has been determined that the brake bands can be reconditioned, we sand blast them to remove all debris and rust. Following sandblasting, the brake bands are then shaped back into original shape. New blocks are then installed on the brake bands.

Before